We offer Advanced NDT testing facilities such as Eddy Current testing, Internal Oxide scale measurement for Boiler tubes Helium Leak testing, Thermography, MFL (Magnetic Flux leakage for tank bottom, Hardness testing by UCI (Ultrasonic Contact Impedance) Method using Kraut Kremer Hardness tester.

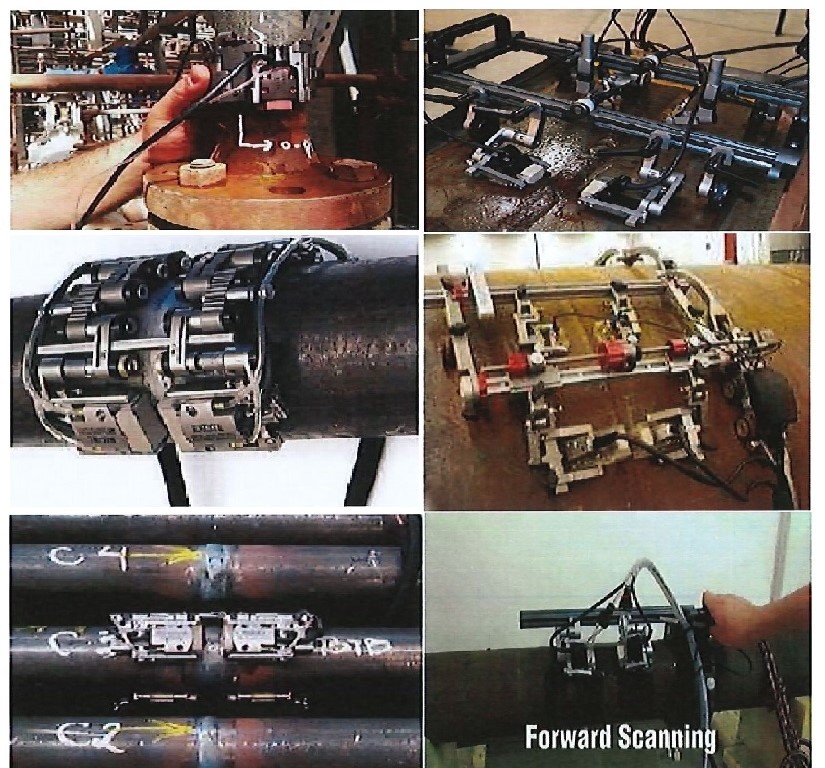

PHASED ARRAY ULTRASONIC TESTING is now offering services of new and upcoming heat Exchanger tube inspection technique PAUT. We utilize Olympus COBRA Scanner or equivalent to inspect smaller diameter pipes and tube welds.

The COBRA Solution kit is a complete scanning solution for the inspections of pipes and tubes ranging from 0.84 in. to 4.50 in. OD (21 mm to 1 14 mm). For the inspection of pipes and tubes situated in close proximity, the COBRA scanner operates within a 12 mm (0.5 in.) clearance. The scanner adheres to the pipe or tube by a spring mechanism, which permits 360-degree scanning, even when only one side of the pipe or tube is accessible. The spring mechanism also enables the COBRA to adhere to nonferromagnetic material.

The COBRA Solution is a semiautomatic system that complies with ASME as well as other inspection codes requiring full data collection and encoding, including addressing the use of ultrasonic in lieu of radiography.

The HSMT-Flex is intended for one axis encoded inspection of circumference welds on pipes of 4.5 in. OD (114.3 mm) and greater. The scanner comes equipped with four probe holders but can be mounted with a total of eight probes with optional probe holders. Mounted probes can be either phased array or conventional UT for most efficient inspections.

The major characteristic of the scanner is its capacity to bend in the center. This allows the scanner to fit on smaller pipes and also to bring the force of the springloaded arm in the radial direction of the pipes for better stability of the wedge, and therefore, optimum data acquisition. For the same reason, optional probe holders that are installed on the outside of the scanner can also pivot.

The HSMT-Flex also allows one of its side frames to slide. This feature allows having the probes mounted on the outside of the scanner. This provides a configuration that is well- suited for hard-to-reach places such as pipe- to-component welds.

The Chain scanner provides a manual pipe-inspection solution for pipes ranging from 45 mm to 965 mm OD (1.75 to 38 in. OD). The scanner, held by chain links instead of magnetic wheels, is well suited for weld or corrosion inspection on various material types, using UT, TOFD, and PA technologies.

The Chain scanner facilitates the manual inspection of pipes with outside diameters of 45 mm to 965 mm (1.75 in. to 38 in.), offering the possibility for twoaxis encoding. The scanner, which is held by chain links instead of magnetic wheels, is able to inspect ferromagnetic or nonferromagnetic surfaces. The chain links also help ensure a straight displacement of the scanner by eliminating steering problems. Finally, it is useful when the area around the pipe is difficult to access as the scanner can be rotated around the pipe using chain links.

Multivalued Nayansh Overseas Consultants & Engineering Services

Regd.Office: Arazi no-668 Vill-Betawar Pargana-Kaswar Raja Tehshil-Sadar Varansi Dist-Varansi (UP) 221011

+91 8355010542

mnoverseasces@gmail.com

With the fast pacing technological advancement and rapid increase in the demand of technical expertise across the globe, MN Overseas Consulants and Engineering remains focused on the present trend and imparts best technical knowledge to the students. It is the best institute in Varansi offering multiple technical courses for the students to select from.

Quick links