Eddy-current testing (ET) is one of many electromagnetic testing methods used in nondestructive testing making use of electromagnetic induction to detect and characterize surface and subsurface flaws in conductive materials.

When it comes to surface applications, the performance of any given inspection technique depends greatly on the specific conditions, mostly the types of materials and defects, but also surface conditions, etc.

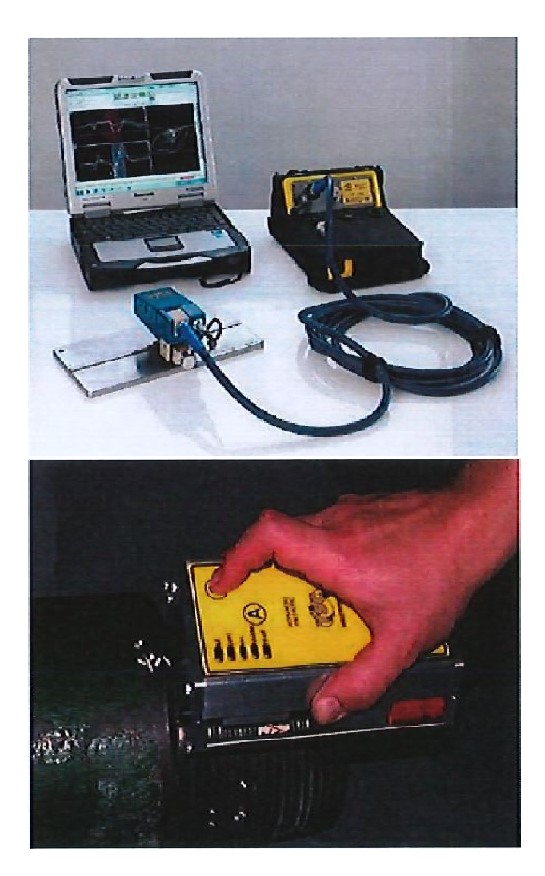

It is an electromagnetic technique for NDT detection and sizing of surface breaking cracks. It was derived from the methods used in eddycurrent testing and works on all metals, ferrous or non-ferrous. Since it doesn't require direct electrical contact with the surface it can work through coatings such as paint or rust.

The method both detects cracks and estimates their size and length. It can inspect any electrically conductive material. Data is recorded electronically for off-line evaluation if necessary and provides a permanent record of indications.

The method and can carry out inspection without removing any protective paint coating. With suitable probes, the method can be used on hot surfaces.

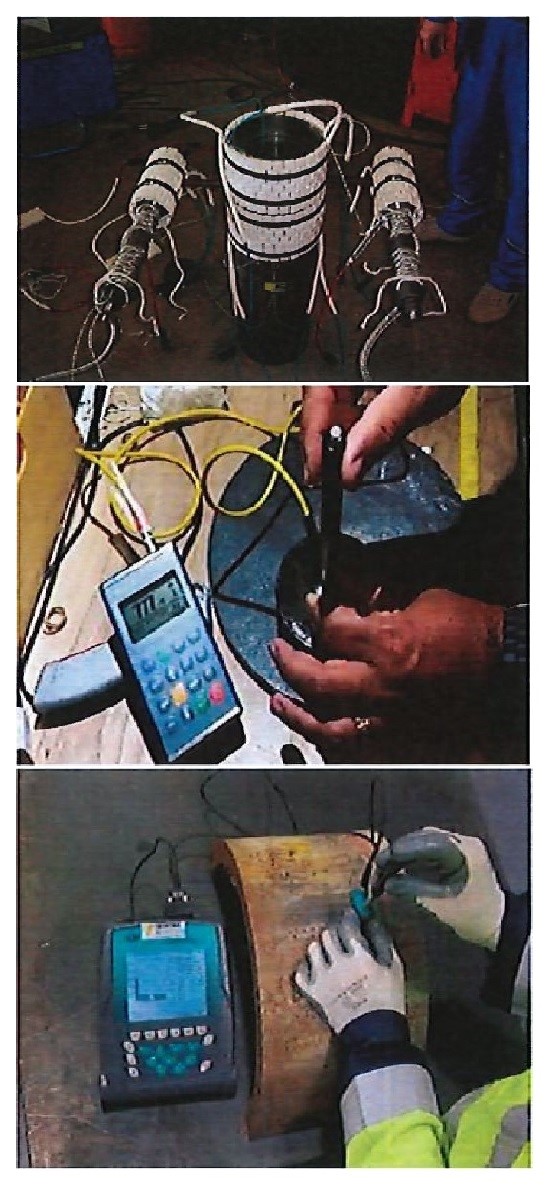

Post Weld Heat Treatment (PWHT) reduces the residual stresses formed during welding. It also restores the macro structure of the steel. Mandatory in high pressure applications, constructors have to strictly follow PWHT requirements to avoid component failures

PWHT eliminates the effects by heating, soaking, and cooling the weld area in a controlled manner to temperatures below the first transformation point, giving the macro structure sufficient time to readjust to its original state and removing the residual stress.

The Leeb rebound hardness test method was developed to provide a portable hardness test for metals. It was developed as an alternative to the unwieldy and sometimes intricate traditional hardness measuring equipment.

Traditional hardness measurements like Rockwell, Vickers, and Brinell, are stationary, requiring fixed workstations in segregated testing areas or laboratories and these methods are selective, involving destructive tests on samples. The portability of Leeb testers can sometimes help to achieve higher testing rates without destruction of samples, which in turn simplifies processes and reduces cost.

We have technical experts in all fields whom can be outsourced to work for both short and long-term basis. Multivalued Nayansh brings forth this type of service helping you find the right person fit for your job requirement.

We have well experienced and Certified Professionals for the following disciplines.

Multivalued Nayansh passion to serve the industry and the quest to develop highly skilled personnel in the field of Quality Engineering and NDT has led us to impart exclusive training courses and certification in this field and to provide continuing education through knowledge updating, skills upgrading, certification and career development to remain right and suitable in the fast-changing economy.

All our training courses are conducted by qualified and highly experienced trainers with up-to-date instructional materials, both locally and overseas. We are conducting day & evening classes at your convenience and time availability.

We provide Training & certifications for the following:

We provide customized training for employer-based certification. Approach us we do provide written practice support and certification.

Our in-depth experience in the field of welding consultancy, training and testing enables us to provide complete welding engineering solutions to our clients. Our engineers are specialized in all welding processes and are trained to handle the various types of material used.

Our Welding, Consultancy, Training & Testing services include:

Multivalued Nayansh Overseas Consultants & Engineering Services

Regd.Office: Arazi no-668 Vill-Betawar Pargana-Kaswar Raja Tehshil-Sadar Varansi Dist-Varansi (UP) 221011

+91 8355010542

mnoverseasces@gmail.com

With the fast pacing technological advancement and rapid increase in the demand of technical expertise across the globe, MN Overseas Consulants and Engineering remains focused on the present trend and imparts best technical knowledge to the students. It is the best institute in Varansi offering multiple technical courses for the students to select from.

Quick links